RAPTOR: AI X-ray System for Semiconductors

In a groundbreaking development for the semiconductor industry, researchers at Purdue University have unveiled RAPTOR (Residual Attention-based Processing of Tampered Optical Responses), an innovative AI-powered 3D X-ray system designed to detect and analyze microscopic defects in semiconductor chips with unprecedented accuracy.

The Critical Need for Advanced Chip Inspection

Semiconductor chips are the backbone of modern electronics, powering everything from smartphones to automotive systems. However, even microscopic defects in these chips can lead to significant problems, including device failures, security vulnerabilities, and safety hazards. Traditional inspection methods are often laborious, time-consuming, and destructive, requiring technicians to physically cut apart defective components to identify issues.

RAPTOR represents a paradigm shift in semiconductor quality control, offering a non-destructive approach that can identify defects during the manufacturing process rather than after chips have been deployed in devices.

How RAPTOR Works

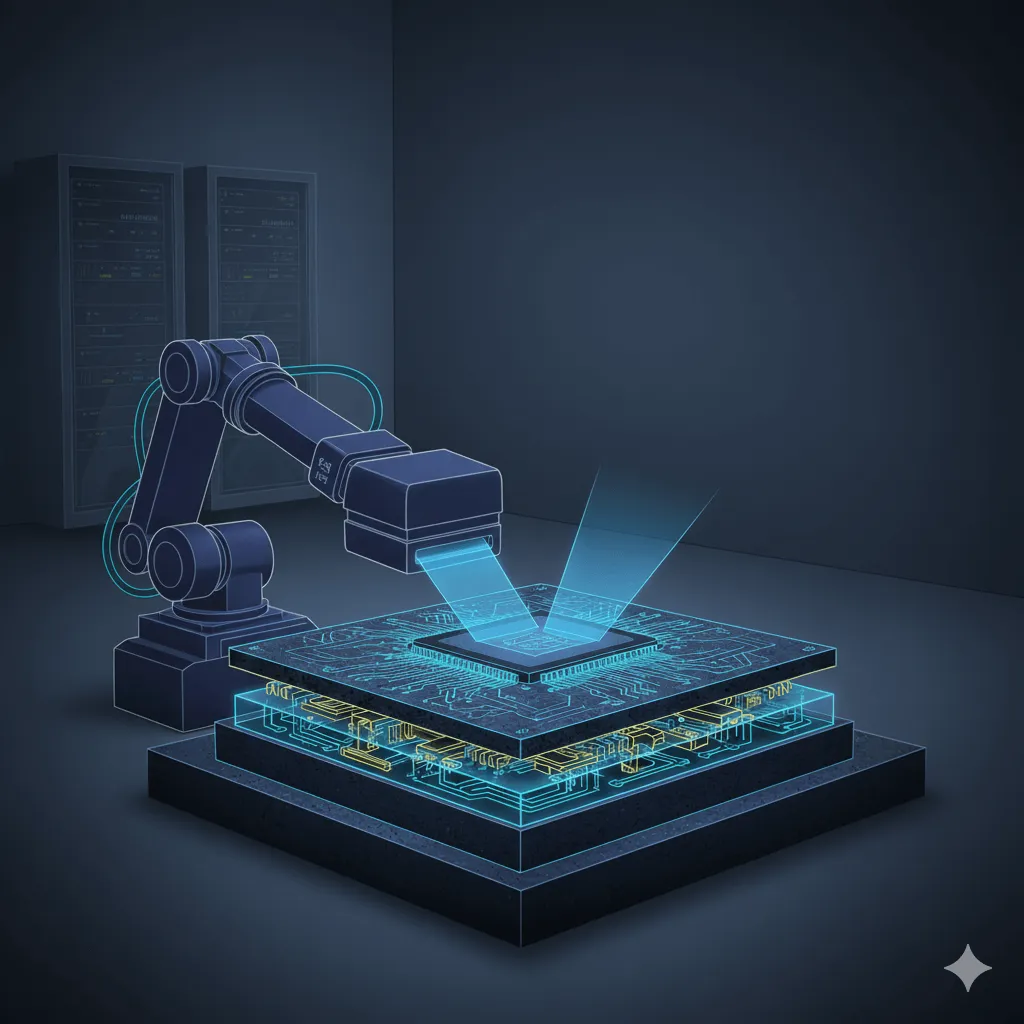

RAPTOR combines cutting-edge X-ray imaging technology with advanced deep learning algorithms to create a comprehensive defect detection system. The technology works through a three-step process:

-

High-Resolution Imaging: Using X-ray tomography at the Advanced Photon Source, a DOE Office of Science user facility at Argonne National Laboratory, RAPTOR creates detailed 3D microstructure images of semiconductor chips.

-

AI-Powered Analysis: Deep learning algorithms automatically process the imaging data to detect defects quickly and accurately, eliminating the need for manual inspection.

-

Predictive Assessment: The system categorizes defects based on their potential to cause problems in the field, allowing manufacturers to prioritize which issues need immediate attention.

Breakthrough Performance Metrics

In testing, RAPTOR has demonstrated exceptional performance, correctly detecting tampering and defects in 97.6% of cases under worst-case scenario conditions. This represents a significant improvement over previous methods:

- 40.6% better than Hausdorff distance methods

- 37.3% better than Procrustes analysis

- 6.4% better than Average Hausdorff distance techniques

The system excels at distinguishing between natural degradation (such as aging or humidity effects) and adversarial tampering, making it valuable for both quality control and security applications.

Revolutionary Technology Behind RAPTOR

RAPTOR leverages gold nanoparticle patterns embedded on chips, analyzing them through dark-field microscopy. The system uses an attention mechanism to prioritize nanoparticle correlations across pre-tamper and post-tamper samples before processing them through a residual attention-based deep convolutional classifier.

This approach allows RAPTOR to construct distance matrices and analyze radii from samples, providing a robust method for detecting even subtle changes in chip structure.

Industry Impact and Applications

The semiconductor industry, valued at over $500 billion globally, faces dual challenges: a shortage of new chips and a $75 billion counterfeit chip market that jeopardizes safety and security across multiple sectors. RAPTOR addresses both issues by:

- Improving Quality Control: Identifying defects early in the manufacturing process reduces waste and improves overall chip reliability.

- Combating Counterfeits: The system’s ability to detect tampering helps protect against malicious modifications that could compromise device security.

- Accelerating Production: By automating the inspection process, RAPTOR significantly speeds up quality assurance compared to traditional manual methods.

Future Developments

The Purdue research team, led by Alexander Kildishev, professor in the Elmore Family School of Electrical and Computer Engineering, is working to convert RAPTOR from a proof of concept into a mature industry solution. Current efforts focus on:

- Collaborating with chip-packaging researchers to innovate the nanoparticle embedding process

- Streamlining authentication steps for integration into existing manufacturing pipelines

- Expanding the system’s capabilities to detect an even broader range of defects and tampering methods

Broader Implications

RAPTOR’s success demonstrates AI’s tremendous potential in the semiconductor industry. As chips become increasingly complex and miniaturized, traditional inspection methods become inadequate. AI-powered solutions like RAPTOR offer a scalable approach to maintaining quality standards while keeping pace with advancing technology.

The system also represents a significant step forward in the fight against counterfeit electronics, which pose security risks in sectors ranging from aviation to personal finance. By providing a reliable method for verifying chip authenticity, RAPTOR helps protect both manufacturers and consumers.

Looking Ahead

As Purdue continues to develop RAPTOR through partnerships with industry leaders, the technology promises to revolutionize semiconductor manufacturing. The integration of advanced imaging with AI analysis offers a glimpse into the future of quality control, where automated systems can detect problems that human inspectors might miss while operating at speeds impossible to achieve manually.

For an industry that touches virtually every aspect of modern life, innovations like RAPTOR are not just improvements—they’re necessities for ensuring the reliability and security of the electronic devices we depend on daily.