Physical AI: The Next Enterprise Revolution

The AI Revolution You Haven’t Heard About

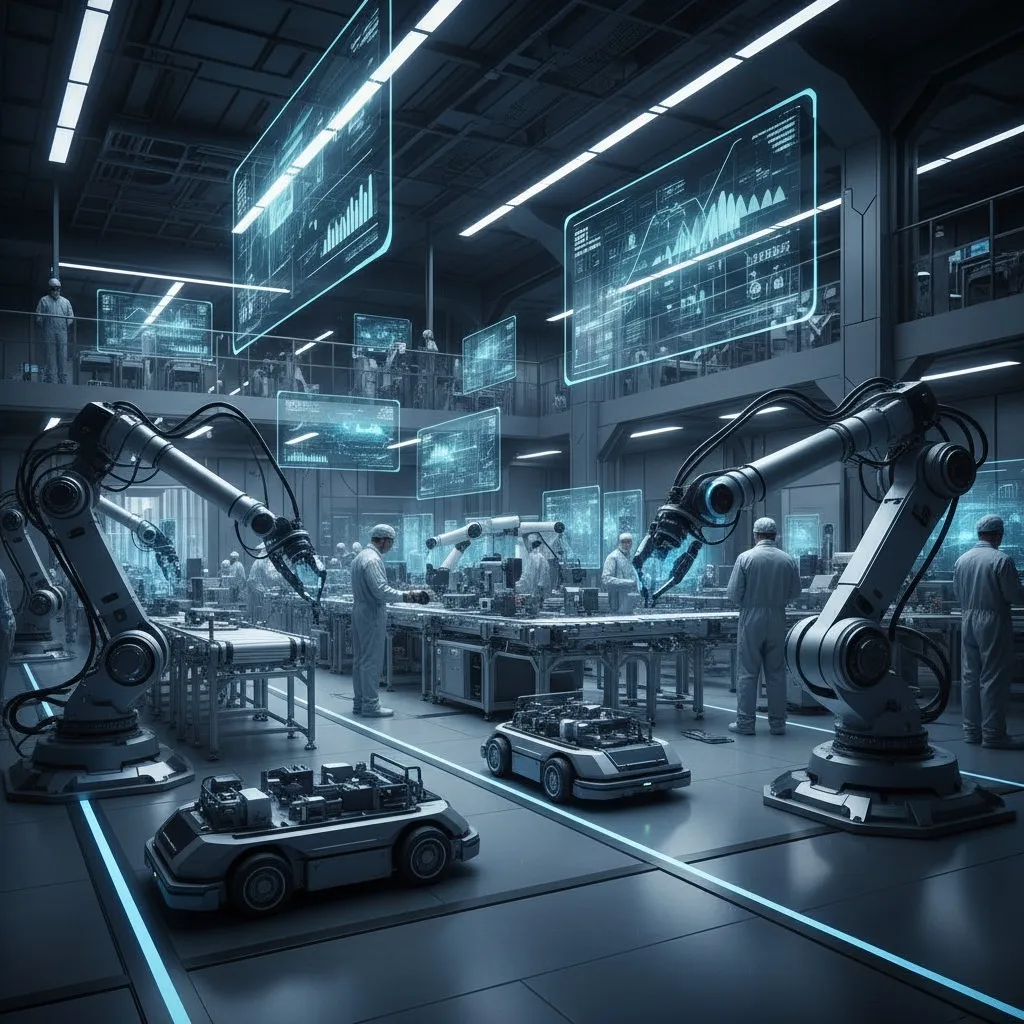

While the tech world obsesses over the latest chatbot capabilities and language model benchmarks, a more fundamental transformation is happening in factories, warehouses, and industrial facilities around the globe. It’s called Physical AI, and it represents the next evolutionary leap from artificial intelligence that lives in software to AI that operates in the real world—thinking, adapting, and acting through robotic systems.

Physical AI isn’t just smarter automation. It’s the embodiment of artificial intelligence in robots and machines that can understand their environment, make decisions in real-time, and adapt to unexpected situations. Think of it as giving AI a body and the ability to manipulate the physical world with the same sophistication that large language models manipulate text.

According to InfoQ’s latest AI trends report, Physical AI represents “the next frontier in AI technologies” and is rapidly moving from research labs to enterprise production floors. Major players like NVIDIA, Google, and Microsoft are betting billions that this technology will fundamentally reshape how work gets done across industries.

Beyond Automation: When Machines Learn to Think

Traditional industrial automation follows rigid programming—if sensor A detects condition B, then execute action C. Physical AI systems operate more like human workers, using multimodal understanding to perceive their environment, reason through complex scenarios, and adapt their behavior based on changing conditions.

Google’s Gemini Robotics On-Device exemplifies this evolution. It’s a vision-language-action (VLA) model that runs locally on robotic devices, bringing multimodal reasoning and real-world understanding directly into the physical world. Instead of following pre-programmed routines, these systems can interpret visual data, understand context, and make intelligent decisions about how to complete tasks.

Microsoft’s approach with their Mu model for Windows Settings demonstrates how Physical AI extends beyond traditional industrial robotics. This lightweight on-device language model processes over 100 tokens per second using Neural Processing Units (NPUs), enabling real-time AI decision-making in everyday business environments.

The key difference? These systems learn and improve continuously. When a Physical AI system encounters a new situation—a differently shaped package, an unexpected obstacle, or a modified workflow—it doesn’t break down. It adapts, learns, and often finds better solutions than human operators initially programmed.

The Enterprise Reality: Where Physical AI Is Already Working

The impact isn’t theoretical. Physical AI is already transforming enterprise operations in measurable ways:

Manufacturing Excellence: Collaborative robots (cobots) equipped with Physical AI capabilities are working alongside human teams in automotive, electronics, and aerospace manufacturing. These systems can handle delicate assembly tasks while adapting to variations in component dimensions or assembly sequences that would stump traditional automation.

Warehouse Operations: Companies like Amazon and FedEx are deploying Physical AI systems that can navigate complex warehouse environments, identify and pick diverse inventory items, and optimize routing in real-time. These aren’t just guided vehicles following predetermined paths—they’re intelligent systems that understand the three-dimensional space and can solve novel logistical challenges.

Quality Assurance: Physical AI systems are performing visual inspections with superhuman consistency and accuracy, identifying defects that human inspectors might miss while learning to recognize new types of quality issues without explicit reprogramming.

Predictive Maintenance: Beyond just monitoring equipment, Physical AI systems can perform hands-on diagnostic tasks, using sensors and manipulators to test components and predict failures before they occur.

The Technology Stack: Making Physical AI Work

NVIDIA’s comprehensive approach illustrates the technological foundation required for Physical AI deployment. Their three-computer solution demonstrates the complexity involved:

- DGX AI supercomputers handle the massive computational requirements for training Physical AI models

- Omniverse and Cosmos platforms on RTX PRO Servers provide realistic simulation environments where AI systems can learn and test behaviors safely

- Jetson AGX Thor processors enable real-time AI inference directly on robotic devices

This infrastructure enables what NVIDIA calls “complete development of physical AI systems, from training to deployment.” Organizations can now train AI models in simulation, test them in virtual environments, and deploy them to physical robots—all within an integrated development pipeline.

The simulation component is particularly crucial. Physical AI systems can learn and practice in virtual environments that would be expensive or dangerous to replicate in the real world, accelerating development timelines and reducing deployment risks.

Trust, Safety, and the Human Factor

One of the most significant advantages of Physical AI over cloud-based systems is edge processing. As Savannah Kunovsky from InfoQ points out, edge computing “lets us design for trust” by keeping data processing local rather than sending sensitive information to remote servers.

This is particularly important in enterprise settings where Physical AI systems may be handling proprietary manufacturing processes, confidential logistics operations, or sensitive facility data. Local processing means companies maintain control over their operational intelligence while still benefiting from advanced AI capabilities.

The safety implications are equally important. Physical AI systems operating in enterprise environments must be designed with robust fail-safes and the ability to work safely alongside human employees. Unlike software AI that operates in controlled digital environments, Physical AI must navigate the unpredictable complexities of the physical world.

The Competitive Advantage: Why Early Movers Win

The enterprises investing in Physical AI now are positioning themselves for sustained competitive advantages. Unlike digital AI tools that can be rapidly deployed across organizations, Physical AI requires integration with physical infrastructure, custom training on specific operational environments, and development of organizational expertise.

This creates significant switching costs and first-mover advantages. Companies that successfully implement Physical AI systems develop organizational expertise that competitors can’t easily replicate by purchasing software licenses or hiring consultants.

The market is responding accordingly. Investment in Physical AI companies has surged, with venture capital firms recognizing that while generative AI may be becoming commoditized, Physical AI requires substantial capital investment and domain expertise—creating natural barriers to entry and sustainable competitive moats.

Implementation Strategies: Getting Physical AI Right

Success with Physical AI requires a fundamentally different approach than digital AI deployment:

Start Small, Think Big: Begin with well-defined, repetitive tasks in controlled environments before expanding to more complex operations. A single robotic workstation performing quality inspections can demonstrate value while teams learn to work with Physical AI systems.

Invest in Simulation: Before deploying expensive robotic hardware, invest in simulation environments where AI systems can learn and operators can train. This reduces risk and accelerates the development of institutional knowledge.

Focus on Human-AI Collaboration: The most successful Physical AI implementations augment human capabilities rather than replacing human workers entirely. Design workflows where AI handles routine physical tasks while humans focus on judgment, creativity, and exception handling.

Build Internal Expertise: Unlike software AI that can be managed by IT departments, Physical AI requires teams that understand both AI technologies and physical operations. Invest in training programs that develop this hybrid expertise.

The Road Ahead: When Every Business Becomes Physical AI-Enabled

Physical AI represents more than just another technological advancement—it’s the bridge between the digital intelligence revolution and the physical world where business value is ultimately created. As these systems become more sophisticated and cost-effective, they’ll transform not just industrial operations but any business process that involves physical interaction.

The companies that recognize this shift early and begin developing Physical AI capabilities now will find themselves with significant operational advantages as the technology matures. Meanwhile, those waiting for Physical AI to become “mainstream” may discover that by then, the competitive landscape has already been permanently altered.

The question isn’t whether Physical AI will transform enterprise operations—it’s whether your organization will be leading that transformation or struggling to catch up.

The age of AI that thinks, learns, and acts in the physical world isn’t coming. It’s here, and it’s moving faster than most businesses realize.

Frequently Asked Questions

What exactly is Physical AI and how does it differ from traditional automation?

Physical AI represents the integration of artificial intelligence with robotic systems that can perceive, reason about, and act in the physical world. Unlike traditional automation that follows pre-programmed instructions, Physical AI systems use machine learning models to understand their environment through sensors and cameras, make decisions based on contextual information, and adapt their behavior to new situations. Traditional automation breaks when conditions change; Physical AI learns and improves from variations in its environment.

Which industries are seeing the most significant impact from Physical AI deployment?

Manufacturing, logistics, and warehouse operations are currently leading Physical AI adoption. Automotive manufacturers use collaborative robots for assembly tasks, e-commerce companies deploy AI-powered picking systems in fulfillment centers, and aerospace companies utilize Physical AI for precision manufacturing and quality control. However, the technology is expanding into healthcare (surgical robotics), agriculture (autonomous farming equipment), and construction (intelligent building systems).

What are the main technical requirements for implementing Physical AI in enterprise settings?

Physical AI requires a three-tier technology infrastructure: high-performance computing for AI model training (like NVIDIA DGX systems), simulation platforms for safe testing and development (such as NVIDIA Omniverse), and edge computing hardware for real-time inference on robotic devices (like Jetson AGX Thor processors). Additionally, organizations need robust networking, sensor integration capabilities, and safety systems designed for human-robot collaboration in enterprise environments.

How do companies typically calculate ROI for Physical AI investments?

Physical AI ROI typically comes from multiple sources: reduced labor costs for repetitive tasks, improved quality and consistency reducing defect rates, increased operational efficiency through 24/7 operation capabilities, enhanced safety reducing workplace accidents and insurance costs, and competitive advantages from faster adaptation to market changes. Most enterprises see payback periods of 2-4 years for well-implemented Physical AI systems, with ongoing operational savings that justify the initial capital investment.

What safety and security considerations are unique to Physical AI systems?

Physical AI security extends beyond cybersecurity to include physical safety protocols since these systems operate in shared human-robot environments. Key considerations include robust fail-safe mechanisms to prevent harmful actions, secure edge computing to prevent unauthorized access to control systems, data privacy protection for sensitive operational information processed locally, regular safety audits of human-robot interaction protocols, and backup systems to maintain operations if AI components fail. Organizations must also consider the physical security of robotic assets and intellectual property embedded in AI models.